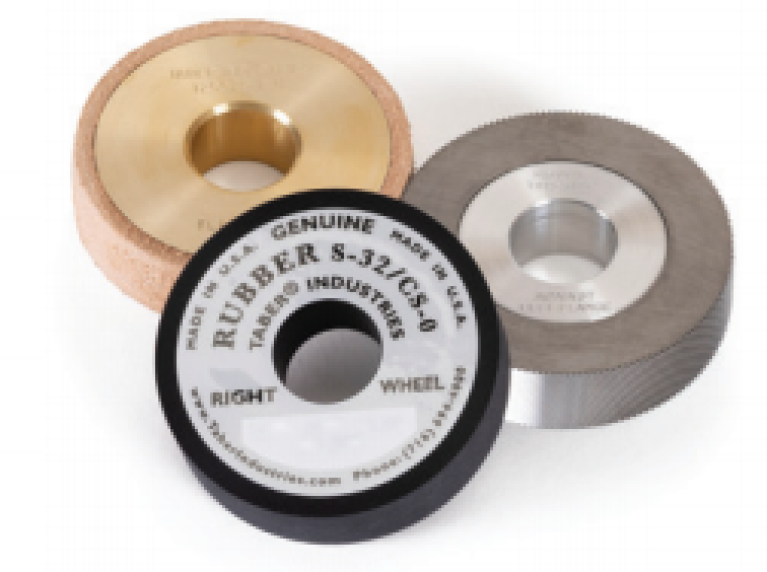

Taber abrading wheels

Used with the Taber Rotary Platform Abraser, two abrasive wheels create the circular wear path recognized as a “Taber test.” As specimens are subjected to the rub-wear action of the wheels, the abrasion marks form a pattern of crossed arcs resulting in a circular ring. This process abrades the sample over all angles of grain or weave, and covers an area approximately 30 cm². Taber abrading wheels are manufactured from a proprietary formulation developed and designed by Taber Industries so the binder material breaks down during use, exposing and creating a fresh abrading surface. Taber offers standardized grades of Genuine Taber abrasive wheels, which have been engineered to meet varying requirements of abrasive action. The choice of abrading wheels should be based upon the wear the specimen material will be subjected to in actual use.

- Offered in a range of wear characteristics

- Calibrase wheels include easy-glide wheel hub

- Sold in pairs

- Shipped in tight-lidded containers to prevent damage

- Premium grade us abrasive materials ensure test repeatability

Others also viewed

More info? Quotation?

Any questions? Don't hesitate to contact us.